So Who Are SCS?

One of the things I’ve wanted to do as part of running a newly formed company, System Controls Solutions, SCS for short, is to establish a blog where I can talk about some of the trials and tribulations of start-up life and what we are up to as a company. The question I kept coming back to though is… what should I write about first?

I’ve got plenty of ideas of topics I want to write about - those who know me know that I’m not short of opinions! In fact, I’ve written a few outlines and even a whole blog post about the Core Values we have selected. I couldn’t quite put my finger on why but it didn’t feel like how I wanted to start this, and so I filed it away and came back and read it a week later. And the question I had whilst reading it was… So Who Are SCS Anyway?

“So Who Are SCS Anyway?”

Well the first part of that is easy – that’s me on the right, Sam Mason, the self-titled Operations Manager for SCS, part owner and founder. Having started my career in engineering before moving into sales with Vanderlande, I had an itch to take on a new challenge. I’ve always liked to push myself and take on more responsibilities, and truthfully I’ve always wanted to head down the self-employment route eventually.

When I first started considering starting a company now, once I started I couldn’t stop thinking of it. And with Covid lockdowns, if there was one thing I wasn’t short on it was time for thinking! Without any dependants, now felt like the perfect time to make this jump, and so I picked up the phone to someone who had done it before.

That person is Dave Ansell, my now Business Partner and the other founder / owner of SCS. Dave established and runs another company based in Michigan, USA called Dynamic Controls Solutions (DCS). Dave has over 30 years of experience of delivering controls solutions for material handling systems, having worked for Dürr for 20+ years prior. Starting out as a controls engineer working across the world, Dave moved to the US in 1996, becoming Director of Engineering in 2003. In 2008, Dave decided that it was time to try and fulfil a long-time ambition of running his own company and formed DCS. Fast forward to today and DCS has established itself as a controls solution provider, with a great reputation and high return rate amongst its customers. As it turned out, Dave had a desire to establish a UK based company too.

Quick-fire facts about DCS:

- Formed in 2008.

- Based in Wixom, Michigan, US.

- Currently 25-30 employees.

- Well established in automotive and warehousing automation markets.

- Worked across North and South America.

We agreed that, as well as feeling like the right time for us personally, it also felt like a good time for the market. We believed that Covid and Brexit would lead to a shake up and large changes in the material handling industry in the UK and Europe. More automation, increased flexibility and market growth. And with that growth, new suppliers would be needed to fill the gap. Having written and agreed our business case, we pulled the trigger;. A few short months after the first idea, SCS was officially formed on December 4th 2020. Armed with a name, a 90 day plan and a business

What is it we do?

Our core focus is to provide controls automation solutions for material handling systems. The PLC systems that run them, the SCADA systems the provide feedback and control, the Human Machine Interfaces for monitoring and input.

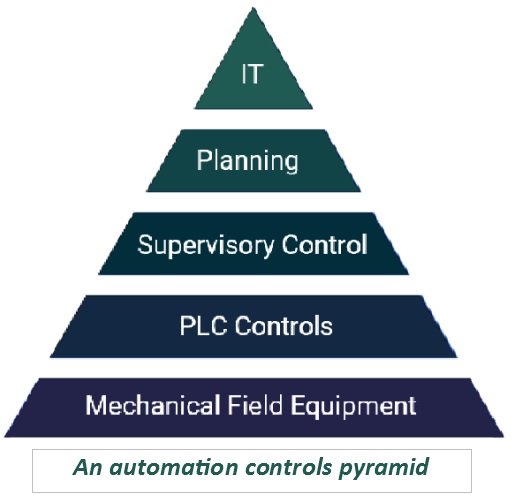

Automated material handling systems use equipment such as conveyors, cranes and robots to move materials for logistics or manufacturing purposes. If you think about the physical system as the skeleton, SCS add the muscles, the controls system, that allows the physical system, the skeleton, to move. There’s also the IT system that tells the controls system what to do, which acts like the brain, planning and managing the processes. Together, this forms the core of what’s known as the controls pyramid, shown to the right. The supervisory controls let you make small, pre-set adjustments on the fly to the PLC controls and planning (part of the IT system) sets the plan for that day.

So that’s what SCS do. In material handling applications, where goods or products are moved by automated systems, we provide the control design of hardware and software that give the material handling system the ability to move. This process could be prompted by planning or management IT system telling the controls what and when to move, or triggered by sensors in simpler applications. Whilst the IT can define where to move, the controls manage the physical processes that actually make the equipment move. SCS will design the controls hardware and software to meet the requirements for the systems operation, produce and procure the required materials, ship it to site and then commission.

If you aren’t from the industry and are thinking

…Sounds complicated, have you got an example?

I do! If you take an application we have all seen (though probably less since Covid started), where you drop a bag at the check-in conveyor at an airport. That conveyor is the first part of a series of conveyors and sorters and screening machines that make up the physical system. This makes up the skeleton in the example above. We then have connections from each conveyor to the control system, the muscles in the example, which will tell motors to start and stop to move the bag based on what the destination is. It gets that destination based off the IT management system, the brain of the operation, which says that bags for your holiday destination go to the output associated with your plane. Our PLC controller knows that the bag is there and where it is going and so it send on/off signals to the conveyors to move the bag through the system.

Whilst that sums up what it is that we provide in simple terms, I do think that there is more to who we are than what we provide. For that, I think we need to talk about how we want to build SCS, and who we want to be also.

We want to be a targeted and focused company, not just in the services we provide, but also in who we provide those services to. We want to work with select customers, who want to work with us, and deliver an unparalleled level of support to them. We want to be a team that companies want to work with, who can be trusted to act with integrity and with our customers best interests at heart. We want to get to know our customers, top to bottom, so that we can deliver the highest possible levels of service, not grow our list of customers as long as we possibly can.

So what’s next?

For now we are still at the start up stage and working hard to establish relationships with companies that we want to work with. We’re 33 days in now to the 90 day plan I mentioned earlier, the core goal of which was to establish and build on relationships. How did we do by the first 30 day milestone in the 90 day plan? Pretty good, but the next 30 days will have just as much challenge I’m sure. The focus now is to continue building customer relationships and now looking to bid on work based on some early leads. The second part is getting ready to put our resource plan into action, so that we are ready to start building our UK team of engineers once our orderbook is ready. Maybe when we hit 90 days I’ll do a follow up blog about our progress against our plan.

On the blog side of things, my hope is that I will be able to make these blog posts regularly, to talk about the challenges we face, the projects we do, and give insight into who we are and what we are doing as a company. If we’re successful in this enterprise, I know that there will come a time when SCS takes over a large part of my life that time will start to fly by. I’m hoping that these blog posts can provide snapshots of SCS’s journey and chart our history as we make it. Will it work? I guess we’ll find out in future blog posts!

Posted by Sam Mason on June, 2021